Model: VK811 PRO,VK812 PRO,VK813 PRO

Size range: DN50-DN500

Pressure range: PN16-PN40

Materials: LCB,GS-C25(1.0619), CF8, CF8M, 904L,etc.

Temperature: -38 to 425 °C

Application: Hot oil system, steam system, molten sale and hot and cold water system etc.

Bellows Sealed Globe Valve,a design that forms a metal barrier between the fluid medium and the atmosphere through automatic roll welding to ensure zero leakage of the valve stem. The bellows globe valve uses a bellows structure. The lower end of the stainless steel bellows is welded to the valve stem through a stainless steel gasket to prevent the process fluid from corroding the valve stem. The other end is placed between the valve body and the valve cover to form a static seal. Double seal design is adopted. If the bellows fails, the stem packing will avoid leakage. The bellows are welded to the stem to maintain stable operation performance, to avoid stem vibration caused by flap vibration. It is most suitable for pipelines with steam, flammable, explosive, thermal oil, high purity, toxic and other media.

1. Standard design of double-layer bellows;

2. Design of heat dissipation valve cover;

3. Design of oil storage device;

4. Design of nut for retaining valve stem by circlip;

5. Reasonable product structure, reliable sealing performance, beautiful appearance;

6. Surfacing Co-based hard alloy on the sealing surface, wear-resistant, corrosion-resistant,long service life;

7. Valve stem quenching and tempering and surface nitriding treatment have good anti-corrosion and anti-friction properties;

8. Valve stem lifting position indication is more intuitive;

9. The material of the parts, the size of the flange and the number of butt welding can be reasonably selected according to the actual working conditions or user requirements to meet various engineering needs.

DIN standard bellows globe valve is suitable for nominal pressure PN1.6~6.4MPa, working temperature -29~350℃, widely used in fluid, high temperature heat transfer oil, liquid ammonia and other media. The key component of the DIN standard bellows globe valve is the metal bellows. The lower end and the valve stem assembly are automatically welded and the upper end is automatically welded to the connecting plate to form a metal barrier between the fluid medium and the atmosphere to ensure zero leakage of the valve stem; The switch is frictionless, the seal is not easy to wear, and the opening and closing torque is small. This kind of globe valve adopts a unique bellows seal design, which completely eliminates the problem of stem packing leakage and meets the most stringent leakage requirements. The zero-leakage feature of the bellows globe valve improves the safety of the equipment, saves a lot of energy, reduces maintenance costs, and provides a clean and safe working environment for industrial applications.

Structural features of DIN standard bellows globe valve

1. The product structure is reasonable, the seal is reliable, and the double sturdy and durable bellows sealing design (bellows + packing) ensures zero leakage of the valve stem. There is no fluid loss, reducing energy loss and improving plant equipment safety. And meet the international sealing standards.

2. The sealing surface is surfacing with Co-based cemented carbide, which is wear-resistant, corrosion-resistant, good friction resistance and long service life

3. The valve stem is quenched and tempered and the surface is nitridated, which has good anti-corrosion and anti-friction properties; the valve stem lifting position indicator is more intuitive

4. Double-layer bellows, convenient maintenance, bellows sealed valve stem, double-sealed position indication, no lifting handwheel

Bellows Globe Valve Manufacturer's Standard:

| Product Standard | |

| Manufacturer's Standard:DIN EN 13709:2003 | Face to Face:DIN EN 558-1 |

| Flange End Standard:DIN 1092-2002 | Welding End Standard:DIN EN 12627 |

| Test Standard:DIN EN 12266 |

|

Pressure Test

| Pressure Test(Table) | |||

| Nominal Pressure | 1.6Mpa | 2.5Mpa | 4.0Mpa |

| Seal Test | 1.8MPa | 2.8MPa | 4.4MPa |

| Shell Seal Test | 2.4MPa | 3.6MPa | 6.0MPa |

| Max. Temperature | 425℃ | ||

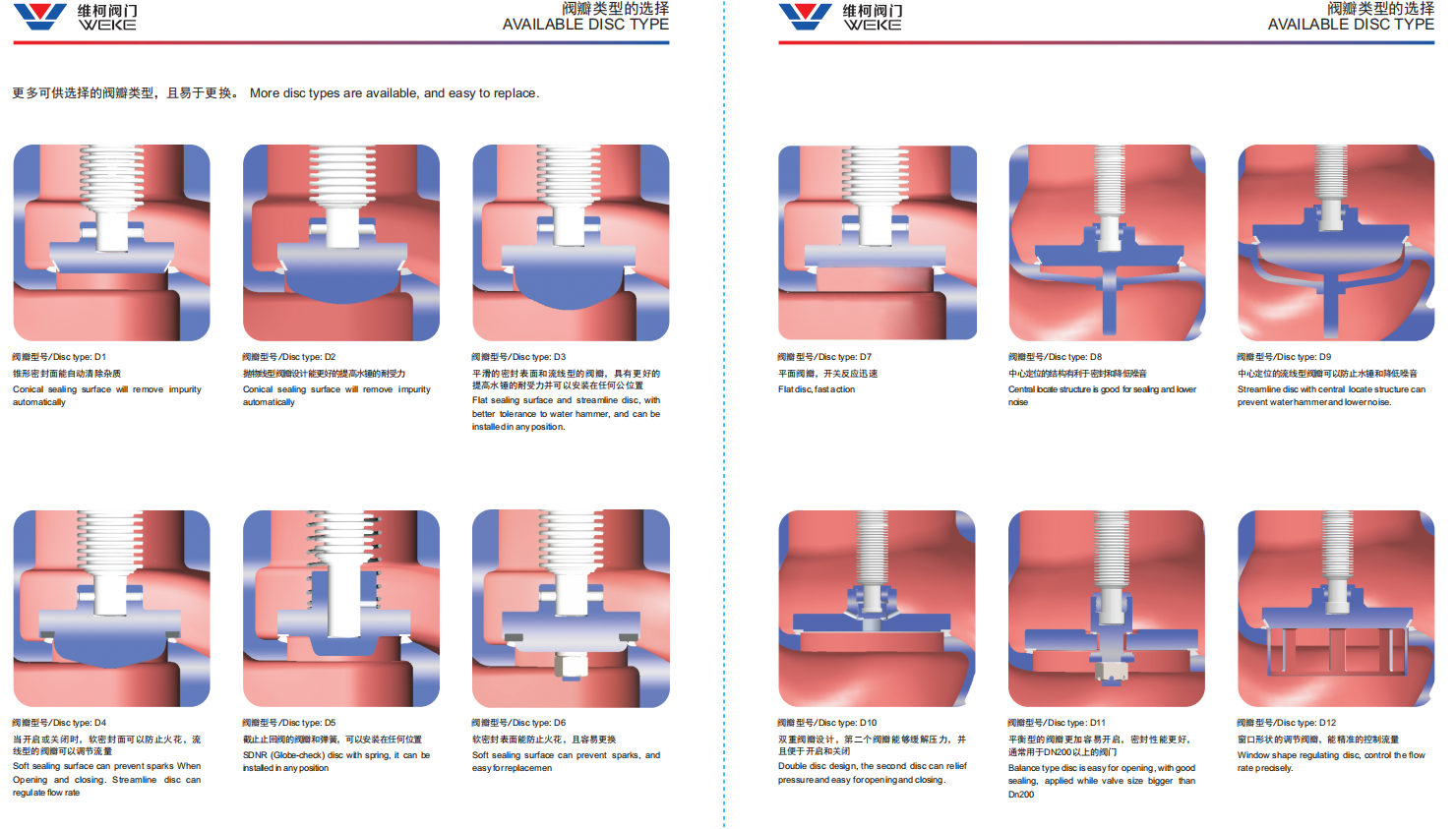

Available disc type

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies.