Lift check valve, also known as one-way valve or check valve, is dependent on the flow of the medium in the pipeline itself and the force generated by the spring and automatically open and close, belongs to a kind of automatic valve. Check valves are used in pipeline systems, their main role is to prevent the backflow of media, to prevent the pump and its drive motor machine reversal, as well as the release of media in the container. Check valves can also be used to supply auxiliary systems where the pressure may rise above the main system pressure. The function of the check valve is to allow the medium to flow in one direction only and to prevent reverse flow. Usually these valves work automatically, with the valve flap opening under the pressure of fluid flowing in one direction; when the fluid flows in the opposite direction, the fluid pressure and the self-weight of the valve flap combine to act on the valve seat, thus cutting off the flow. One of the female thread check valve, butterfly check valve belongs to this type of valve, it includes swing check valve and lift check valve.

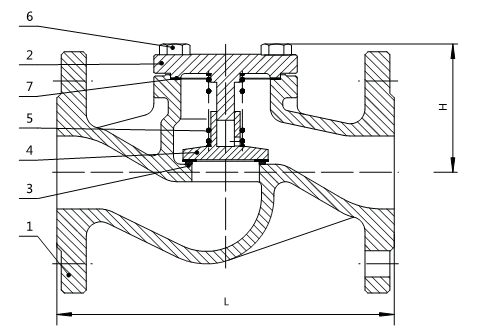

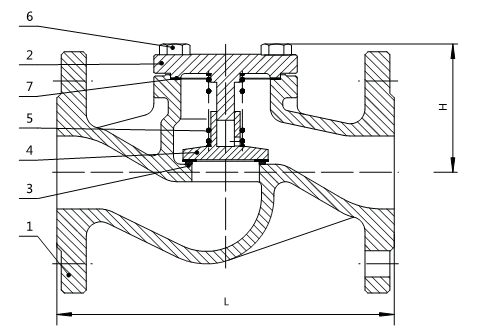

The lift check valve has a flap located on the sealing surface of the seat on the valve body. This valve is like a globe valve except that the flap can be raised and lowered freely, the fluid pressure causes the flap to lift from the sealing surface of the valve seat and the media return causes the flap to fall back onto the seat and cut off the flow. Depending on the conditions of use, the valve flap can be of all-metal construction or in the form of a rubber gasket or ring inlaid on the flap frame. Like the globe valve, the passage of fluid through the lift check valve is narrow, so the pressure drop through the lift check valve is somewhat greater than that of the swing check valve, and the flow of the swing check valve is very little restricted.

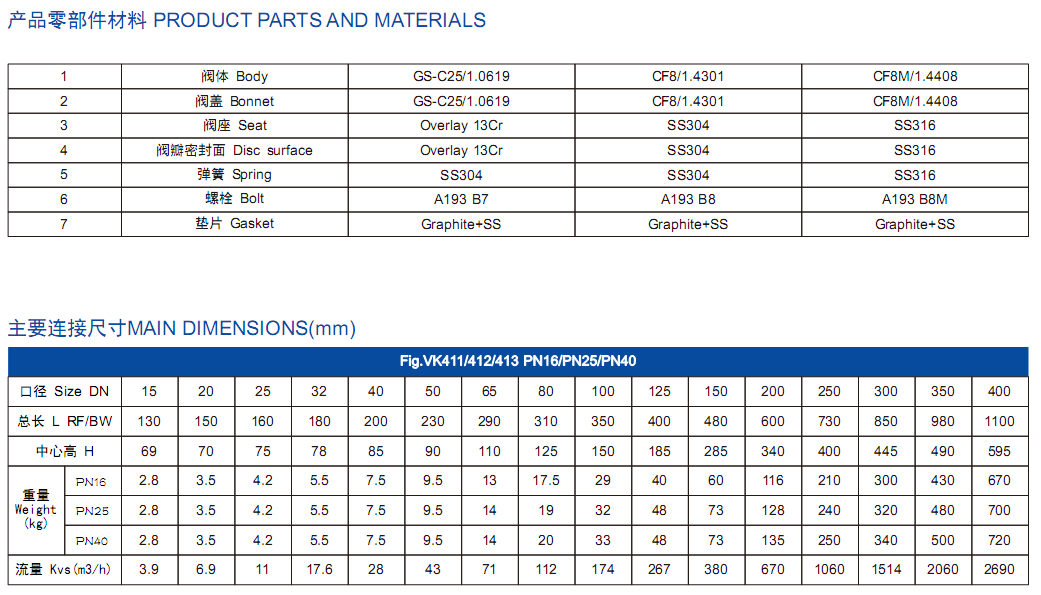

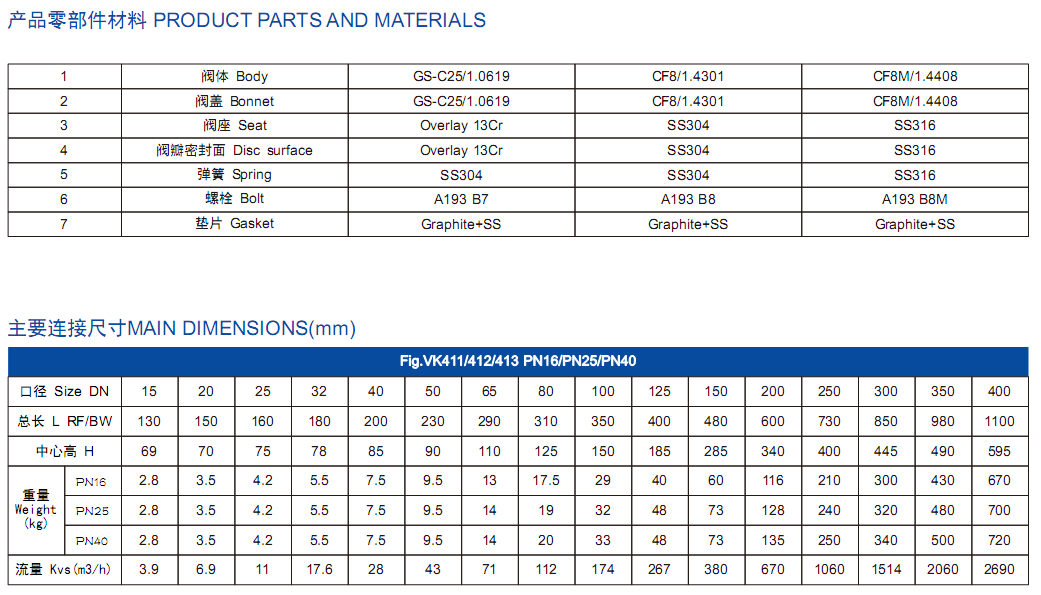

Design and manufacturing standards: GB/T 12235, DIN EN 13709

Connection flange standard:GB/T 9113, DIN EN 1092-1

Pressure and temperature class: GB/T 12224-2005,,GB/T9131, ANSI/ASME.B16.34

Test and inspection standards:GB/T 13927-2008, DIN EN 12266